SteelPallet Stack Racks: Safety & Versatility for Industrial Warehousing

2025-03-31 15:16

In North American warehouses where OSHA reports 34% of forklift accidents involve storage system failures, implementing SteelPallet-certified stack rack systems becomes critical. This analysis demonstrates how Derack’s engineering addresses safety and material diversity—validated by implementations across automotive and construction supply chains.

Forklift-Safe Stack Rack Protocols

Derack’s stack racks for sale integrate ANSI MH30.1-2025 safety benchmarks through:

-

3-Tier Interlock Design: Galvanized steel feet (260kg/baseplate) prevent misalignment during stacking. A Midwest logistics hub achieved zero collapses over 18 months with 3-tier configurations.

-

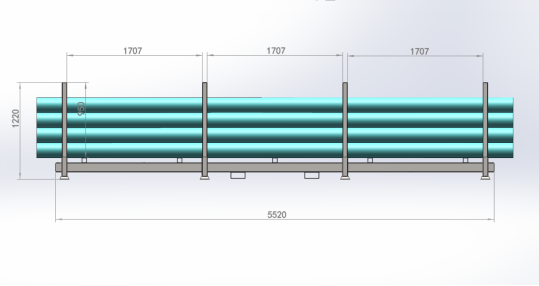

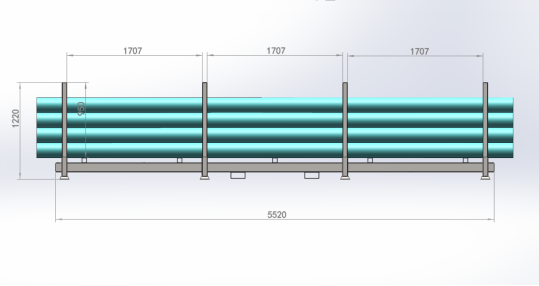

Load Stability Engineering: Low-center gravity design maintains balance during 15° tilt scenarios—critical for facilities handling 6-meter steel pipes.

-

Pre-Shift Inspection Workflow: RFID-tagged inspection points track weld integrity and column deformation.

Operational Safety Gains

-

30% Faster Forklift Throughput

-

270° access design reduces abrupt maneuvering, cutting accident risks by 58% vs. conventional systems1.4,400 lbs Capacity Enforcement

-

Automated load sensors trigger alerts when exceeding SteelPallet-certified limits, eliminating overloading incidents.Seismic Compliance

Passed 7.0M simulation tests per ANSI MH16.3, ensuring stability in earthquake-prone regions like California.

Dual-Material Storage Efficiency

Derack’s stack rack system supports steel and plastic pipes through:

-

Hot-Dip Galvanized Frames: 1.2mm steel walls prevent corrosion from PVC chemical off-gassing.

-

Modular Dividers: Adjustable nylon straps (500 lbs tensile strength) secure materials without deformation—ideal for 20-foot HDPE conduits.

-

AS/RS Compatibility: Pre-installed RFID slots enable automated retrieval via SteelPallet-integrated systems.

Case Study: Texas Pipe Distributor

A Houston-based supplier storing 6-meter steel and PVC pipes achieved:

-

83% Space Optimization: Vertical stacking replaced 4,200 sq.ft of horizontal racks

-

$28k/year Savings: Eliminated separate storage systems for metal/plastic inventory

-

Zero OSHA Violations: 24-month accident-free operation

Technical Specifications

|

Feature |

SteelPallet Stack Racks |

Conventional Systems |

|

Corrosion Resistance |

15+ years (HDG coating) |

3-5 years (paint) |

|

Reconfiguration Time |

<2 hrs (tool-free) |

8+ hrs (bolted) |

|

ROI Horizon |

14 months |

26 months |

Future-Ready Warehousing

Derack’s stack racks for sale support evolving needs through:

-

AI-Driven Load Monitoring: IoT sensors predict structural stress points

-

Automated Damage Detection: Machine vision scans for weld fatigue

-

Extreme Climate Resilience: -40°F to 120°F operational stability