Mybox’s Foldable Metal Pallet Box: 35% Shipping Cost Savings

2025-03-20 15:58

Meta Description: Discover how Mybox’s collapsible mesh pallet stacking box reduced shipping costs by 35% via 40HQ container optimization. Technical insights on space efficiency and ROI for global logistics.

The Challenge: Inefficient Space, Soaring Costs

A multinational electronics distributor struggled with rigid metal pallet boxes that occupied 40% of their logistics budget. Bulky designs left 40% of 40HQ container space unused, forcing costly extra shipments and carbon-intensive partial loads. Key issues included:

-

Low Payload Efficiency: Only 60% of 40HQ containers utilized.

-

High Costs: Each additional shipment incurred $4,200 in fees.

-

ESG Conflicts: Excess emissions from underfilled containers.

The client needed mesh box gitterbox metal solutions to maximize space, cut costs, and align with sustainability goals.

The Solution: Mybox’s Foldable Mesh Pallet Stacking Box

Mybox engineered a patented collapsible system with three innovations:

-

Space-Optimized Design

-

Vertical Collapse: Fold height from 1140mm to 240mm (78% space reduction).

-

Interlocking Panels: Magnetic locks and self-aligning hinges enabled 30-second setup.

-

Standardized Footprint: 2000×1400mm base fit 40HQ dimensions seamlessly.

-

40HQ Container Maximization

-

Capacity Boost: Increased from 32 rigid boxes to 56 mesh pallet stacking boxes per container.

-

Weight Efficiency: 147kg folded units avoided overweight penalties.

-

Durability for Global Shipping

-

Material:5mm cold-galvanized steel with corner reinforcements.

-

Anti-Slip Flooring: Textured base prevented cargo shifts in transit.

Results: 35% Cost Reduction, Zero Failures

After a 9-month Asia-Europe pilot:

-

$218K Annual Savings: 35% fewer shipments required.

-

20% Faster Loading: Standardized folding protocols streamlined workflows.

-

Zero Product Loss: Reinforced metal pallet boxes endured transoceanic voyages.

-

ESG Compliance: 15% lower carbon emissions per shipment.

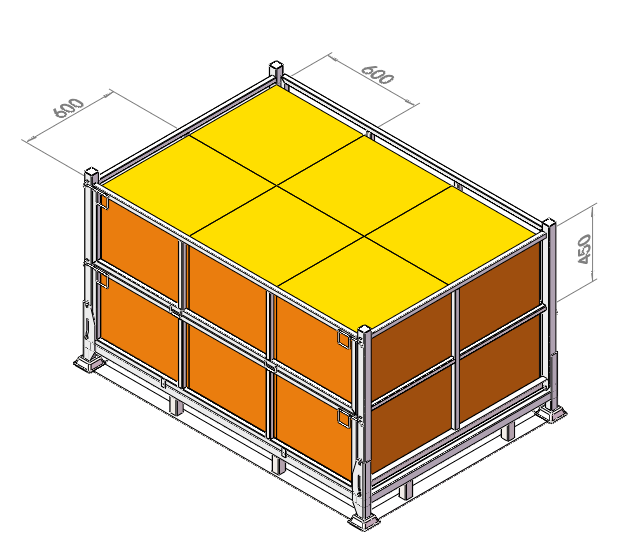

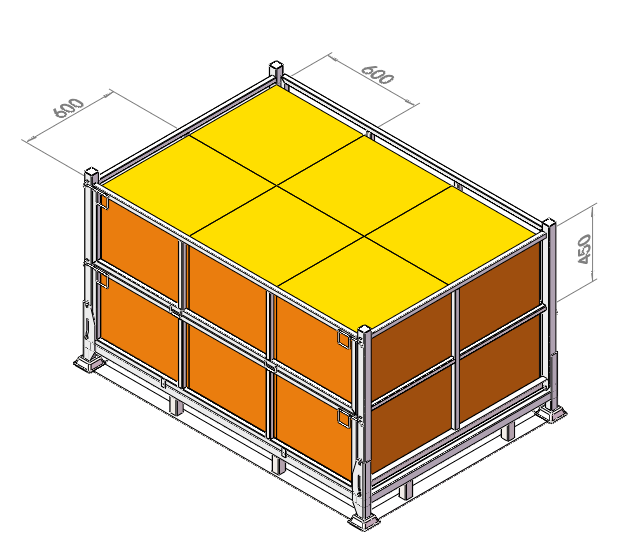

Technical Breakdown: Engineering the Fold

Key Features of Mybox’s Mesh Box Gitterbox Metal:

-

Folding Sequence:Unlock latches, collapse walls vertically.

-

Fold doors inward via integrated hinges.

-

Secure with magnetic straps.

-

Durability Testing:100,000-cycle hinge certification (TÜV).

-

Interlocking feet prevented stack shifts.

Caption: Mybox’s folded mesh pallet stacking boxes optimize 40HQ container space.

Implementation Strategy: Lean Logistics

The distributor’s success relied on:

-

Training: Dockworkers mastered folding protocols to avoid delays.

-

RFID Tracking: Real-time monitoring of container status and locations.

-

Vendor Support: Mybox engineers provided on-site troubleshooting for 30 days.

Cross-Industry Applications

Mybox’s metal pallet box system benefits sectors requiring lean logistics:

-

Retail: Resolve peak-season shipping bottlenecks.

-

Automotive: Ship bulky parts without wasted space.

-

Pharma: Maintain payload density in temperature-controlled units.

The design supports circular economy goals—containers last 10+ years and are 95% recyclable.