Mybox Pallet Cages: Extend Lifespan & Scale Storage Efficiently

2025-03-25 15:25

Meta Description: Discover how a global manufacturer extended pallet cage lifespan by 5+ years while scaling storage from 100 to 10,000 units. Proven strategies and ROI data inside.

The Challenge: Premature Failure & Inflexible Storage

A Fortune 500 electronics manufacturer faced dual crises:

-

40% Failure Rate: Pallet cages required replacement within 3 years due to bent bases and rust.

-

Growth Bottlenecks: Legacy systems couldn’t scale beyond 1,000 units, forcing costly off-site rentals.

The client needed a solution to prolong container life and enable seamless scaling.

The Solution: Mybox’s Dual-Action Framework

-

Prolonging Pallet Cage Lifespan in 4 Steps

-

Quarterly Inspections: Laser-measured corner posts (±2mm tolerance) and ultrasonic corrosion checks.

-

Forklift Training: Reduced base damage by 80% with centered loading (aligned within 50mm).

-

Part Replacements: Upgraded hinges (50,000-cycle rated) and polyurethane wheels for pallet cages with wheels.

-

Predictive Analytics: RFID tags tracked load cycles, forecasting maintenance needs with 90% accuracy.

-

Scalable Storage Ecosystem

-

Phase 1 (100–1,000 Units): Standardized 1200×1000mm pallet cages with lids (2-ton capacity).

-

Phase 2 (1,000–5,000): AGV-compatible bases and RFID tracking enabled robotic handling.

-

Phase 3 (5,000–10,000+): Global supply chain sync with dual-sourced, ISO 9001-certified steel.

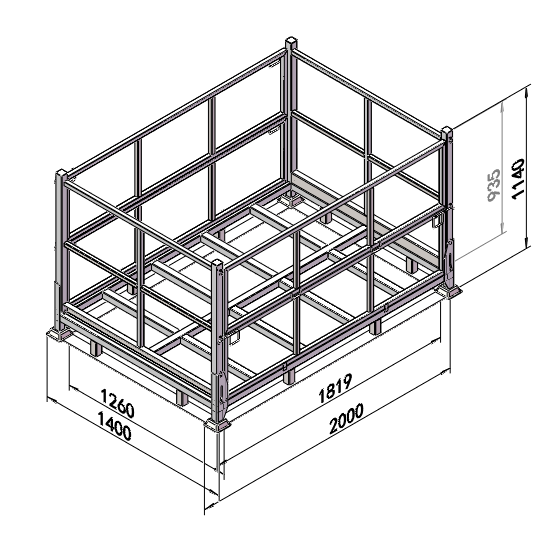

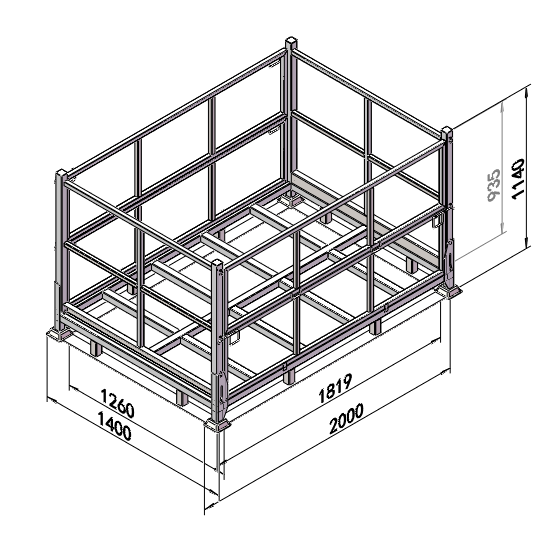

Caption: Mybox’s modular pallet cages with wheels in a high-density automated warehouse.

Results: 5+ Years Added & 60% Cost Savings

Lifespan & Efficiency

-

90% of units passed 10-year recertification; 95% operational availability.

-

40% faster inventory turnover via RFID tracking.

Financial Impact

-

297K/yearsavedonmaintenance;3.2M avoided in off-site storage costs.

-

50% cost recovery through refurbished pallet cages for sale.

Technical Innovations

-

Corrosion Resistance

-

Cold-galvanized spray (20μm) restored protection for pallet cages in humid zones.

-

Scalability Engineering

-

Interlocking feet (±1mm tolerance) ensured compatibility across 10,000+ units.

-

Bolt-on lids and mesh doors allowed rapid reconfiguration.

-

Global Compliance

-

Meets EN 13698-1 (EU) and OSHA standards for cross-regional deployments.

Client’s Success Strategy

-

Preventive Training: Forklift operators certified in load-centering protocols.

-

Circular Economy: Retired pallet cages for sale refurbished for secondary markets.

Why Mybox Works Across Industries

-

Automotive: AGV-ready pallet cages with wheels streamline EV battery handling.

-

Retail: Secure lids protect high-value goods during transit.

-

Pharma: Scalable systems adapt to cold-chain storage demands.