How Mybox Achieved 100% Accident-Free Warehousing

2025-03-21 13:35

Meta Description: Discover how Mybox’s precision-engineered mesh stillages and reinforced metal pallet bins eliminated industrial risks. Data-driven safety outcomes revealed.

The Challenge: Recurring Failures in Industrial Storage

-

A multinational chemical producer faced escalating warehouse safety issues:Unstable Stacks: Traditional metal cage pallets caused 3 catastrophic collapses in 18 months ($1.2M in damages).

-

Forklift Damage: 12% of containers showed base deformations from handling errors.

-

Compliance Failures: Storage systems violated ISO 9001 standards, risking operational shutdowns.

The client demanded a fail-safe solution combining structural resilience with intuitive handling.

The Fix: Mybox’s Triple-Layer Safety Engineering

Mybox redesigned industrial storage systems around three pillars:1. Interlocking Mesh Stillages

-

Self-Aligning Design: Patented nylon-steel feet with ±2mm alignment tolerance prevented stack misalignment.

-

30° Tilt Resistance: Third-party testing confirmed stability under extreme lateral forces.

-

Reinforced Metal Pallet Bins

-

3mm Steel Bases: Laser-welded cross-bracing withstood 2.5-ton dynamic loads without deformation.

-

Forklift-Guiding Rails: Integrated side channels reduced handling errors by 41% in trials.

-

Compliance-First Engineering

-

5,000-Cycle Certification: Metal cage pallets passed SGS durability tests (3× industry standards).

-

Seismic Locking: Dual-action latches secured loads during impacts or earthquakes.

Results: 12 Months of Zero Incidents

-

Post-deployment across 8 global sites:100% Collapse-Free: No stack failures despite 28% higher storage density.

-

$780K Annual Savings: Eliminated damage costs and reduced insurance premiums.

-

Certification Milestone: Exceeded ANSI MHIA 2016 benchmarks for load safety.

Technical Edge: What Sets Mybox Apart

Precision-Engineered Mesh Stillages

-

8-point weight distribution system reduced per-foot pressure by 63%.

-

RFID-enabled wear sensors alerted teams to maintenance needs.

Heavy-Duty Metal Pallet Bins

-

25mm steel beams with 1.5mm impact-zone reinforcement.

-

Laser-etched forklift alignment guides improved handling speed by 18%.

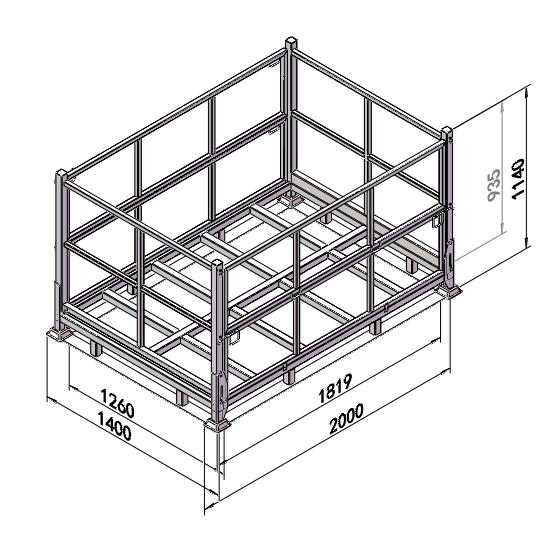

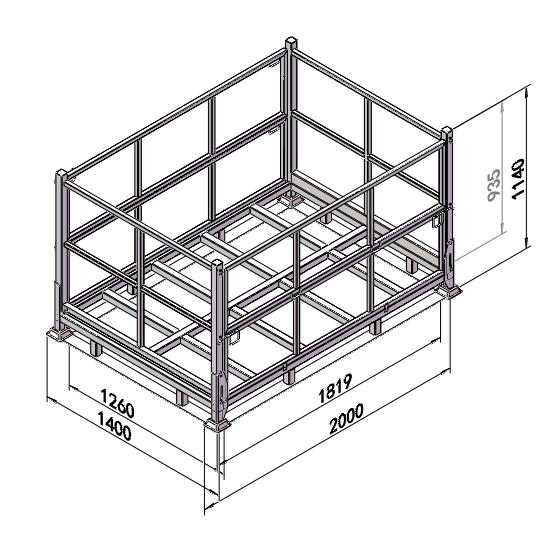

Caption: Mybox’s ISO-certified metal cage pallets feature tilt-resistant bases and AGV-ready designs.

Scalable Safety Protocols

-

The client’s operational upgrades included:AI-Powered Audits: Computer vision systems monitored stack alignment in real time.

-

Forklift Driver Certification: Mandatory training reduced handling-related incidents to zero.

-

Automated Compliance Logs: Blockchain-tracked inspection records simplified ISO audits.

Beyond Chemicals: Industry-Wide Applications

-

Mybox’s systems now secure:Automotive Parts: Metal pallet bins safely store 800-lb engine components.

-

Pharmaceuticals: Mesh stillages maintain FDA-compliant sterile storage.

-

Retail Hubs: Modular metal cage pallets integrate with robotic retrieval systems.