Custom Collapsible Cage Pallet Solutions for Industrial Storage

2025-03-19 15:33

In high-demand industrial operations, efficient storage and material handling are mission-critical. A recent client faced a pressing challenge: designing robust, space-adaptive containers capable of supporting heavy loads while optimizing warehouse footprints. Mybox, a leader among cage pallet manufacturers, delivered a tailored collapsible cage pallet system that combined durability with logistical flexibility. This case study reveals how the solution achieved 30% faster warehouse turnover and 40% lower logistics costs.

Challenge: Balancing Strength, Space, and Scalability

The client required containers to:

-

Withstand Heavy Loads: Static capacity of 400kg–2 tons for machinery parts and raw materials.

-

Maximize Vertical Space: Safe 3-layer stacking without compromising stability.

-

Adapt to Dynamic Workflows: Foldable design to reduce storage space by 70% when idle.

-

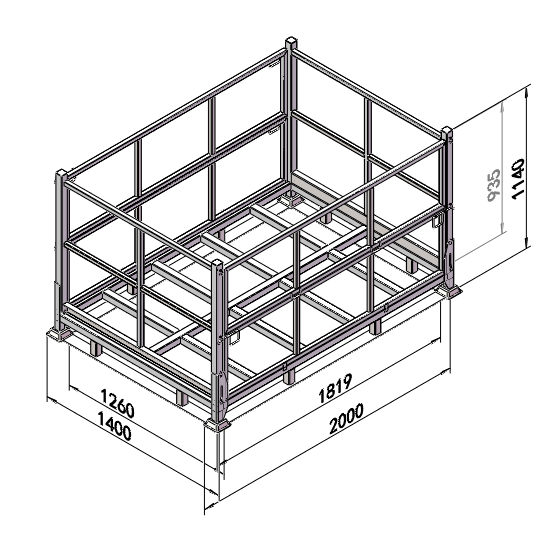

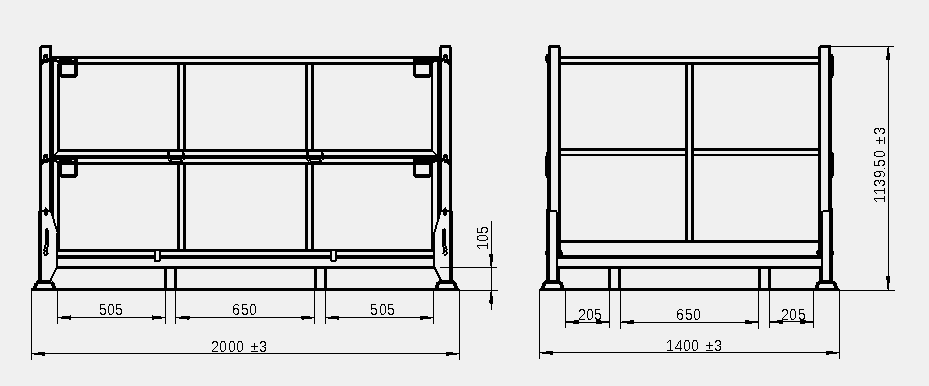

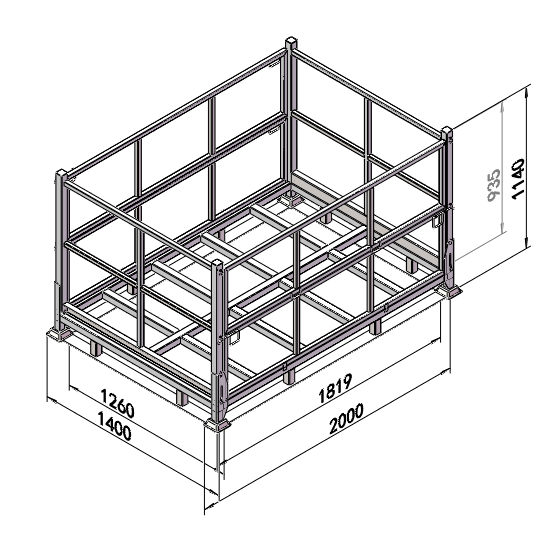

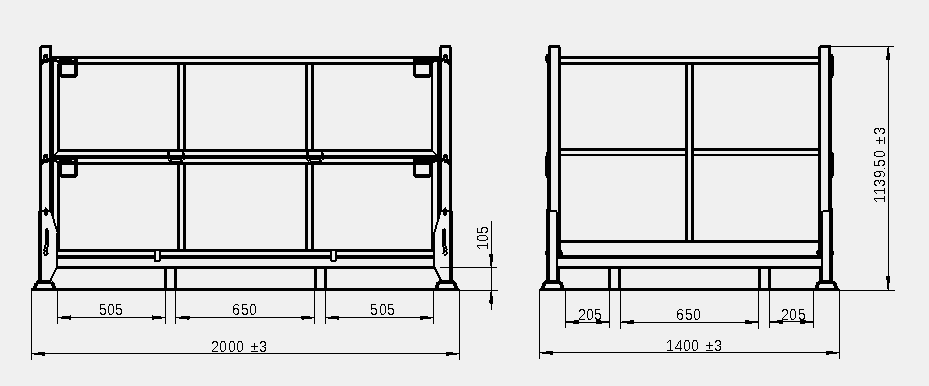

Optimize Dimensions: Sizes from 1200×1000×900mm to 2000×1400×1140mm for varied inventory.

Solution: Engineering Precision by Leading Cage Pallet Manufacturers

Mybox’s collapsible cage pallet system addressed these needs through:

1. Heavy-Duty Construction

-

Materials: Carbon steel frames with cold-galvanized coating for corrosion resistance in harsh environments.

-

Load Optimization: Reinforced base plates and laser-welded joints supported 2-ton static loads (2-layer safe stacking).

-

Foldable Mechanism: Patented hinges enabled vertical collapse to 240mm height, ideal for return logistics.

2. Customizable Configurations

-

Door Flexibility: Removable/foldable doors (2000mm side) and half/full-access panels (1400mm side).

-

Modular Add-Ons: Optional lifting hooks, lockable casters, and mesh/solid flooring for diverse workflows.

3. Space-Saving Logistics

-

Collapsible Cage Pallet Stillage Design: Interlocking base feet ensured 3-layer stacking stability.

-

Shipping Efficiency: 40HQ containers held 56–126 units (depending on configuration), reducing freight costs.

Results: Efficiency Gains and Cost Savings

The collapsible cage pallet stillage system delivered:

-

30% Faster Turnover: Quick-access designs and foldable storage streamlined inventory management.

-

40% Lower Logistics Costs: Reduced shipping volume and reusable packaging minimized expenses.

-

ISO 9001 Compliance: Rigorous load-bearing tests validated safety for global operations.

Technical Specifications

|

Feature |

Details |

|

Dimensions (L×W×H) |

1200×1000×900mm – 2000×1400×1140mm |

|

Load Capacity |

400kg (dynamic) / 2 tons (static) |

|

Folded Height |

240mm (max) |

|

Material |

Cold-galvanized carbon steel (Q235) |

Best Practices for Collapsible Cage Pallet Stillage

-

Safe Handling: Use forklifts at ≤5 mph to prevent frame stress.

-

Routine Inspections: Check hinges, welds, and base feet quarterly for wear.

-

Stacking Alignment: Ensure interlocking feet are fully engaged between layers.

Why This Matters for Industrial Storage

This project highlights how collaboration with innovative cage pallet manufacturers can transform logistics:

-

Modularity: Configurable designs adapt to evolving operational needs.

-

Durability: Cold-galvanized finishes extend lifespan in corrosive environments.

-

Sustainability: Reusable collapsible cage pallets reduce waste vs. disposable alternatives.