3-Layer Stacking Cuts Warehouse Costs 40%

2025-03-19 15:35

In global logistics, where warehouse space directly impacts profitability, one industry leader faced a crisis: 95% facility utilization and unsustainable storage cost hikes. Mybox’s collapsible pallet stillage cage system transformed their operations, achieving 40% space savings and ISO-certified safety. Here’s how.

The Crisis: When Storage Limits Threaten Growth

The client’s warehouses struggled with:

-

Crippling Space Shortages: Traditional rigid containers occupied 30% excess floor space.

-

Safety Risks: Unstable 3-layer stacking led to frequent near-collapses.

-

Soaring Costs: Annual storage expenses rose 15% due to inefficiencies.

Solution: Foldable Steel Pallet Systems Engineered for Efficiency

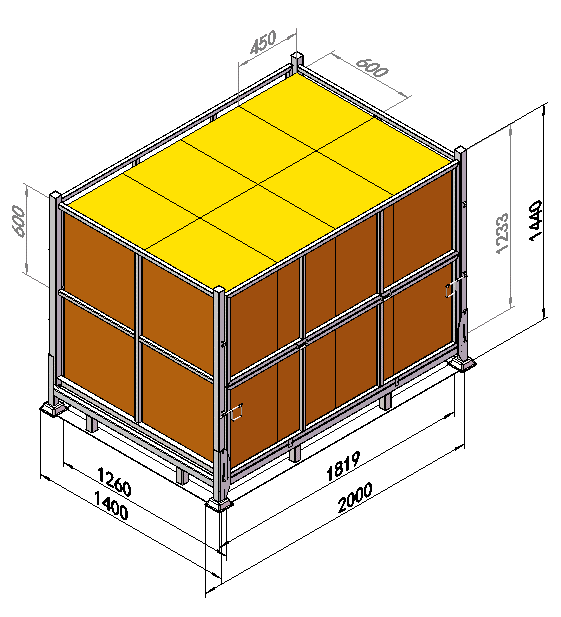

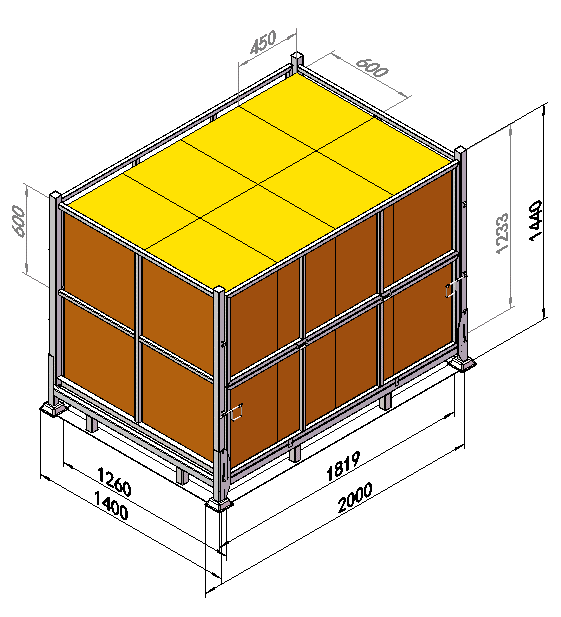

Mybox delivered a collapsible stillage solution combining space optimization with industrial-grade durability:

1. Space-Smart Design

-

Collapsible Pallet Stillage Cage: Walls and base fold vertically to 240mm height, reducing idle storage volume by 70%.

-

Precision-Built Dimensions: 2000×1400×1140mm (external) fits standard racks; internal space holds 8 sub-containers.

-

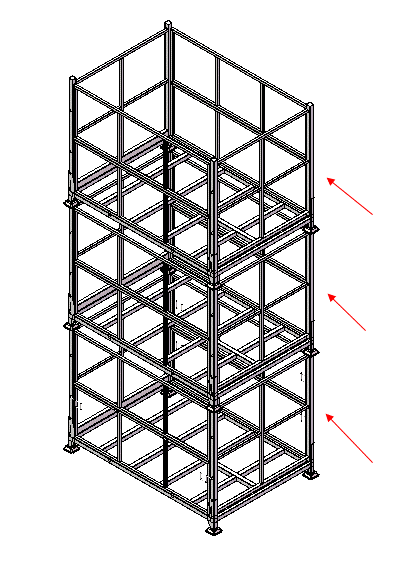

Interlocking Safety: Patented base feet eliminate tilt risks during 3-layer stacking.

2. Heavy-Duty Performance

-

Foldable Steel Pallet Construction: Cold-galvanized carbon steel frames withstand 2-ton static loads.

-

Reinforced Base: 3mm steel plates and cross-bracing support 12-ton total stacked weight.

3. Logistics Cost Control

-

40HQ Shipping: 56 folded units per container reduced transportation costs by 35%.

Results: 40% Space Savings & Operational Reinvention

Post-implementation outcomes:

-

40% Floor Space Freed: Vertical stacking maximized warehouse cube utilization.

-

30% Lower Storage Costs: Compact folding reduced container storage needs.

-

Zero Safety Incidents: ISO 9001-certified 3-layer stacking protocol ensured collapse-free operations.

Technical Edge: The Science Behind 3-Layer Stacking

-

Base Layer: Anti-slip mats prevent shifting on warehouse floors.

-

Stacking Integrity: Interlocking feet and lateral braces distribute weight evenly.

-

Load Capacity: Reinforced corner posts support 400kg dynamic loads per collapsible stillage

Safety First: Best Practices from the Field

-

Forklift Protocols: Operators trained to handle foldable steel pallets at <5 mph to prevent deformation.

-

Monthly Inspections: Hinges, welds, and alignment checks maintain structural integrity.

-

Load Discipline: Strict 400kg dynamic load limits enforced during transport.

Why This Innovation Matters

Mybox’s collapsible pallet stillage cage system proves that smarter storage drives competitive advantage:

-

Scalability: Modular designs adapt to seasonal inventory spikes.

-

Sustainability: Reusable systems reduce waste vs. single-use alternatives.

-

Profitability: Every 10% space saving boosted the client’s margins by $120,000 annually.